US$324.62 *

Prices plus shipping costs

Ready to go! In your hands soon. (see shipping costs for details)

- Order number: SW050006-001

- GTIN-13 (EAN) 4018754268856

- Suppliernumber: 50184005

- Weight: 0.78 Kg

- Customs tariff number: 82041100

- Country of origin (COO):

Germany

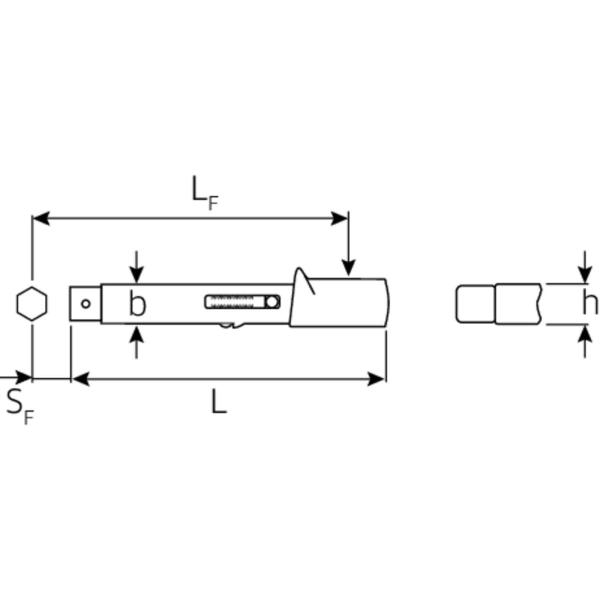

Model Torque range Resolution Width (B) Length (L) Insert size 730/5... more

| Model | Torque range | Resolution | Width (B) | Length (L) | Insert size | ||

| 730/5 Quick | 6-50 Nm | 5-36 ft·lb | 2 Nm | 1 ft·lb | 28mm | 315mm | 9x12mm |

| 730/10 Quick | 20-100 Nm | 15-74 ft·lb | 2.5 Nm | 2.5 ft·lb | 28mm | 370mm | 9x12mm |

| 730/12 Quick | 25-130 Nm | 20-95 ft·lb | 2.5 Nm | 2.5 ft·lb | 28mm | 410mm | 14x18mm |

| 730/20 Quick | 40-200 Nm | 30-147 ft·lb | 5 Nm | 5 ft·lb | 28mm | 455mm | 14x18mm |

| 730/40 Quick | 80-400 Nm | 60-300 ft·lb | 10 Nm | 10 ft·lb | 28mm | 590mm | 14x18mm |

| 730/65 Quick 1) 2) | 130-650 Nm | 100-480 ft·lb | 20 Nm | 20 ft·lb | 30,6mm | 875mm | 14x18mm |

| 730II/65 Quick 2) | 130-650 Nm | 100-480 ft·lb | 20 Nm | 20 ft·lb | 30,6mm | 897mm | 22x28mm |

| 730a/5 Quick | 6-50 Nm | 50-440 in·lb | 2 Nm | 10 in·lb | 28mm | 315mm | 9x12mm |

| 730a/10 Quick | 20-100 Nm | 180-880 in·lb | 2.5 Nm | 20 in·lb | 28mm | 370mm | 9x12mm |

| 730a/12 Quick | 25-130 Nm | 225-1150 in·lb | 2.5 Nm | 25 in·lb | 28mm | 410mm | 14x18mm |

| 730a/20 Quick | 40-200 Nm | 350-1750 in·lb | 5 Nm | 50 in·lb | 28mm | 455mm | 14x18mm |

1) recommended ratchet insert tool No 735/40HD

2) supplied in textile bag

- click-type

- the measuring element is only under load while force is being applied, no need for manual reset to zero

- mount for interchangeable insert/shell tools

- QuickRelease safety lock (sizes 5–65)

- rapid setting thanks to easy-action locking lever in the handle (sizes 5–65)

- ergonomically designed, non-slip adjuster with a thumb recess

- magnifying glass integrated in the display window

- optimised convex handle for strain-free working

- dual stop signal

- twin scales N·m/ft·lb and N·m/in·lb (sizes 5–80)

- on request also available as an N·m-only version without twin scale (sizes 5-65)

- can be applied for either clockwise or anticlockwise tightening by turning the inserts over

- any force applied to the tool after the 'click' or applied in the opposite direction to the current function – e.g. forcible loosening of a jammed screw - does not act on the trigger mechanism and cannot cause damage to it

- calibration using perfectControl® calibrating unit No 7794 or calibration system No 7706. Readjustment does not require disassembly.

- certificate in accordance with DIN EN ISO 6789-2:2017

- display deviation value ± 4%

Viewed